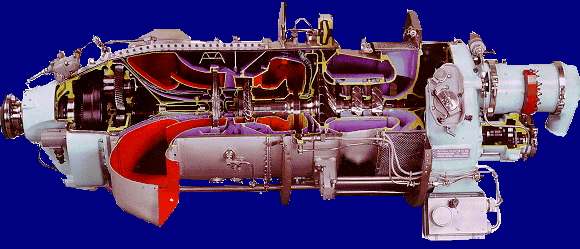

The GE M601 series engine was originally designed for L-410 commuter. GE

M601 is turboprop engine with free power turbine.

The M601 engine is reverse

flow engine. It has two independent parts: the gas generator and the power part.

The gas generator and free turbine shafts are arranged in a tandem layout. Air

enters the engine in the rear part, flows forward through the compressor,

combustion chamber and turbines and exits through exhaust nozzles near the front

of the engine.

Gas Generator

Air enters the compressor in a radial direction through a protecting screen

and annular plenum to the first stage of axial compressor. The compressor

consists of two axial stages followed by one centrifugal compressor stage. The

combustor chamber is a annular configuration with a low maintenance combustor

and fuel distribution system. During operation part of the air flow is directed

through a flame tube through the perforations in the wall, the remainder passes

through the hollow nozzle guide vanes of the gas generator turbine. The fuel is

atomized by a special spray ring rotating with the gas generator shaft. A

single stage gas generator turbine drives the compressor section through a

direct drive shaft. The interturbine temperature (ITT) is measured by 9

thermocouples installed in the flow path at the gas generator turbine

outlet.

Propeller Gearbox

A tip shrouded single stage axial-flow power turbine drives the propeller

through a two stages countershaft reduction gearbox. The reduction gearbox

embodies an internal torquemeter which provides for signal for the cockpit

installed torque or power indication instruments. The exhaust gases from the

power turbine pass through a annular plenum to the atmosphere via two exhaust

nozzle. The high velocity and high temperature exhaust gases provide additional

jet thrust adding to the performance of the airplane.

Fuel and Starting System

The fuel system of the engine is a low pressure system with an engine driven

geared fuel pump and the engine is started by an electric starter/generator.

Two torch igniters provide the initial flame for starting.

Lubrication System

The oil system is an internal pressure system with an integral oil tank

incorporated in the accessory gearbox. The oil system provides lubrication and

cooling for bearings and for many internal areas the engine. The engine oil is

also used for the torque indication system and propeller governor operation.

Engine Limiter Systems

The engine is equipped with limiters which prevent overtemperature and

overspeeding during starting and reverse thrust operating conditions. The

limiters indicate the exceedence of permitted operating pramaters of

temperature, torque, engine rotating speeds of the gas generator and

propeller.

Engine Control

The operation is managed through three cockpit levers. One controls the

engine shaft power during positive and reverse propeller blade angle

operations. One lever actuates the fuel shut-off valve and if an emergency

circuit is on, controls the engine power. The third lever controls the

propeller rotation speed and provides emergency feathering and engine

shutdown.

Sky Tractor is proud to announce that we

are a dealer for Johnson Conversions!

This conversion will update your Thrush, Air Tractor, or Ag Cat to the

dependable GE M601-E11 jet turbine.

Why you should consider the GE M601 TurboProp Engine?

- Reliable 751 SHP

- Easy to operate

- Auto Start System

- Easy to maintain

- No Hot Section inspections

- Excellent support

- No fuel nozzles to inspect and clean

- Very competitive price

- STC'd for Ag Cat, Air Tractor, Thrush

Why you should consider modifying your present

aircraft with the Johnson Conversion

- High cost of new turbine aircraft

- Dealers offering less in trade-in value because

of large supply of used aircraft

- Update your good ag aircraft Increase production

- Increase working speed Increase load carrying

ability

- Improved handling and flying characteristics

- Put the FUN back into the spraying job

- Consider the quality of the Johnson conversion

- Consider the cost of the Johnson conversion

Why you should consider purchasing your Johnson

Conversion from Sky Tractor Supply

- Knowledgeable sales staff

- Highly trained service personnel

- Excellent industry reputation

FREQUENTLY ASKED QUESTIONS?

B1 - What is TBO of

M601 engine?

TBO of M601 depends on the engine

model and version.

The TBO requirement are set based on flight hours, operating cycles and calendar

time. If the engine passes a limit in terms of hours or cycles it must be returned to an authorized GE M601 major repair facility for overhaul.

If the calendar time limit is reached and the engine still has hours and

cycles remaining prior to overhaul, the

engine maybe sent to the overhaul facility for Shop Revision to extend the

calendar life or for overhaul. Shop revision restores the full calendar life,

but does not change the engine status in terms of hours and cycles. Example: If the engine has

900 hours and 1500 cycles till overhaul, after a normal Shop Revision the cycles

and hours remain unchanged and the full

calendar life is re-instated.

B2 - I have purchased a new M601 engine. The engine logbook shows a shorter calendar

life than published in some of the GE documents. Can my engine be

operated to the published calendar limit?

This discrepancy is caused by the way the engine was certified with our certifying authority, the CAA. The Calendar

limit of any M601 is currently 8 years . Your engine can be operated to

the full 8-year calendar limit using the field inspection processes defined

in the engine Maintenance Manual. The two mandatory

inspections are necessary at the 5th and 7th year of

operation. The first inspection after 5 years extends the calendar

life of the engine by 2 years and the

inspection at 7th year extends the calendar life one additional year. These

inspections include borescopic inspection of internal parts, replacement of o-rings and other rubber parts,

performance and operational checks. The

inspection requires only a few man hours by a GE qualified technician and is accomplished with the engine installed on the

aircraft.. The calendar limit is then extended by a logbook entry noting

approval to continue the engine in service. Your logbook shows the calendar

life till the next inspection or overhaul.

B3 - When I look at the M601 engine data sheets, the weights shown are heavier than similar

competing turboprop engines. What is the

real weight difference?

Yes, according to the data sheets

the difference in mass seems higher than

other engines of similar powers. GE a.s. shows the data of engine as it is delivered including all the devices

included with the standard engine. The GE M601 is delivered fully equipped with most of the basic accessories necessary for operation of the

engine. Many of these accessories are

not included with our competitor’s engines. This is why the M601 appears to be heavier. The M601 requires less oil and includes more

accessories in the basic weight, which decreases the installed weight

difference. If you compare the installed engine weight of equally equipped engines, including Oil and

accessories , the M601 is about 20

pounds heavier than the competing engines.

B4 - Can you explain how optional bulletin "Cancellation of service life

limits and of fixed number of overhauls at all GE M601 engine models"

dated September 5, 2002 influences the TBO of the engines? Does

this mean the flight cycle limit was cancelled?

This is a misunderstanding caused

by the translation of the wording from

the Czech language to English. This bulletin addresses an old Life Limit that

has been removed and does not address the TBO intervals.

When first introduced the M601

was approved with an ultimate Life

Limit. The engine was limited to being

overhauled only two times. When the

engine reached it’s 3rd Overhaul it was considered un-airworthy.

The mentioned bulletin states that this Overhaul Life Limit has been cancelled and now there is no limit

in terms of number of times the engine can be overhauled.

Time between overhauls is not

affected by this bulletin The applicable Maintenance Manual and Engine

Logbook for your engine should be used to determine the TBO and when maintenance

is required.

B5 - In the logbook

of our M601E engine manufactured 1993, overhauled 1997, the TBO is given to be

2000 hours. In your promotional materials about M601E-11 engine I have read the

TBO is 3000 hours. Is this a new TBO applicable on our M601E?

Engines manufactured after January 1998 any

new M601E series engine (i.e., M601E, E-11 etc.) have been manufactured with

hardware applicable to the TBO of 3000 hours. Overhauled engines may have been

overhauled for a TBO of 2000 hours or - if upgraded during overhaul – they may

have a 3000 hour TBO. Your engine can be upgraded during the next overhaul

to the status of 3000 hours

TBO.

There are following options of

overhauls of original (2000 hours TBO) M601E/E-11 engines:

2000 hours 2250

cycles (standard)

Following upgrade options are

available at the time of Overhaul for additional costs:

2000 hours 4000

cycles

3000 hours 3300 cycles

3000 hours 6600 cycles

B6 - I have M601D,

can you upgrade it the M601E Model?

We are sorry, but even though on

the first view basically all M601 engines look very similar, the internal

differences between the M601D and M601E

are extensive. The costs associated

with the upgrade of engines from any model to different configuration (e.g., from

D to E or from E to F) are not considered economically acceptable.

You may wish to trade your engine for a later mode and GE can assist you

with an exchange.

B7 - I have seen an

advertisement mentioning some problems

associated with the operation of the M601 in arctic

operations.

No, this is a rumor started by our

competition. The M601 engine was designed from the very beginning to operate

in the extremely cold conditions in Siberia where they have been in service for more than 25 years

with no problems. M601E-11 is certified for ground start in temperature ranges

of –50 up to +40 deg C ( down to – 20

deg C without engine preheating, down to –50 deg C with engine preheating).

The absence of fuel nozzles and the benefit of an electronic start controller

provides one button starting to minimize starting difficulties in any climatic conditions.

B8 - I purchased an engine from someone else and it has no logbook, can GE

produce a new logbook and will GE Overhaul the engine?

The logbook duplicate can be

released only in in case that the original logbook was lost or destroyed if the

engine is fully airworthy (incl. calendar life in the moment of duplicate

production). To accomplish this, we need: the Engine serial number, number of

hours and cycles flown since the last repair, spoiled original logbook (if it

exist), or some evidence that the original logbook does not exist or was

destroyed or stolen (police protocol about theft, accident or other). The

logbook duplicate will be filled in using the data available from company

production records.

Yes, we can overhaul such an

engine, but since we do not have appropriate data about the previous service

life, we will assume the most unfavorable cases and all life limited parts will

be exchanged. This will result in a higher than normal Overhaul

cost.

B9 - Who can repair

my engine?

Overhaul can only be performed by GE Czech SRO in Prague major repairs

can be done in the US by certified repair facitlities, and general planned

inspections and other routine engine work can be done by Authorized Service

Centers who employ technicians with proper training. Other line maintenance is provided by GE a.s. European staff, by the staff

at GE or GE Russia. Heavy maintenance up to and including shop revision

can be accomplished by GE Overhaul requires the engine to be returned

to the GE shop in Czech Republic. Additional Major Service

Centers are being added in other parts of the world.

B10 - Does GE have engines available for rental if my engine fails and how

long will it take to repair my engine?

Yes, we have prepared engines for

AOG situations. These engines are provided free of charge if the requirement for

repair of your engine was the fault of Walter.

B11 - I am looking to purchase a GE M601 engine, how much fuel will the engine

use?

Fuel consumption depends on the specific engine model, flight conditions,

power used and characteristics of individual engine installation. Basic

fuel burn infomationis available in the certification status report.

GE provides basic specific fuel consumption data for individual engine

models on request, please address your question to Marketing Department.

B12 - What is the reliability of the GE M601 engine?

GE a.s. is certified aircraft engine manufacturer. The reliability of the

GE M601 engine is carefully documented. Reliability data for the

M601 engines are comparable with that of other turboprops engine manufacturers

of the same power ranges. For updated statistical data please ask

Marketing Department.

B13 - I am planning

to purchase an M601 from an individual, what should I look for before purchasing

the engine?

If engine is older than five years from overhaul, it has to have had a

calendar extension to continue to be maintained and recognized by GE. GE

will not support an engine of 2000 TBO beyond the tbo limitations either

hourly or by calendar. We recommend you to ask for the Certification Status

where you receive basic information about the engine. You need to

examine the engine logbook to determine the hours and cycles to TBO along

with the calendar life. If the engine is installed in an airplane

you should ask for a demonstration run to verify engine performance.

As a final step in you decision process you may wish to ask

GE to check the status of the engine through factory records. For

this you should contact Marketing Department with engine serial number.

B14 - Can my

A&P Mechanic perform the 300-hour inspections required by the Maintenance

Manual?

To assure properly perform the 300-hour inspections your mechanic should

have attended the GE training.

B15 - Can I burn Diesel Fuel in my GE M601 Engine?

No, diesel fuel is not approved for the M601 engines. Use

of a un-recommended fuels may cause serious damages to the Fuel Control Unit

seals which could result in fuel control problems and loss of power

in-flight.

B16 - What is the cost of operation of the GE M601?

Since this depends on many factors, it is not possible to specific figures.

Basically the economy is depending on costs of maintenance, costs of fuel

and other additional costs like insurance. Routine Maintenance costs

are very low due to the very low maintenance requirements. Depending

on specific engine model, fuel consumption is comparable with the other

turboprop engines in the same power class.